2025-01-16

What are engineering plastics?

Engineering plastics are high-performance plastic materials that can withstand high temperatures, strong tensile forces, and chemical corrosion, making them ideal for producing durable products. For example:

- Polypropylene (PP): Lightweight, highly resistant to chemicals, suitable for pipes, containers, and automotive components.

- Polyethylene (PE): High toughness and impact resistance, widely used in industrial pipelines and cable sheathing.

- Acrylonitrile-Butadiene-Styrene (ABS): High hardness and impact resistance, commonly found in electronic device casings and automotive interiors.

- Polyethylene Terephthalate (PET): With high wear resistance, strong rigidity, and low friction coefficient, it is used in food packaging, electronic components, and mechanical parts.

- Polycarbonate (PC): Known for high transparency, excellent impact resistance, and dimensional stability, it is used in bulletproof glass, lighting covers, and automotive parts.

- Nylon (PA): With high strength, wear resistance, and good heat and chemical resistance, it is commonly used in gears, bearings, and industrial machine parts.

- Poly (methyl methacrylate) (PMMA): With high transparency and weather resistance, it is suitable for outdoor and optical applications, commonly used in vehicle tail lights and architectural decorative materials.

- High Impact Polystyrene (HIPS): Known for its excellent impact resistance and good processability, it is commonly used in manufacturing durable housings and packaging materials.

Due to their high added value and broad application, the production process of these materials inevitably generates waste, such as off-spec pipes and sheets. Efficiently recycling these engineering plastics is not only a cost-effective approach but also a crucial step toward green manufacturing.

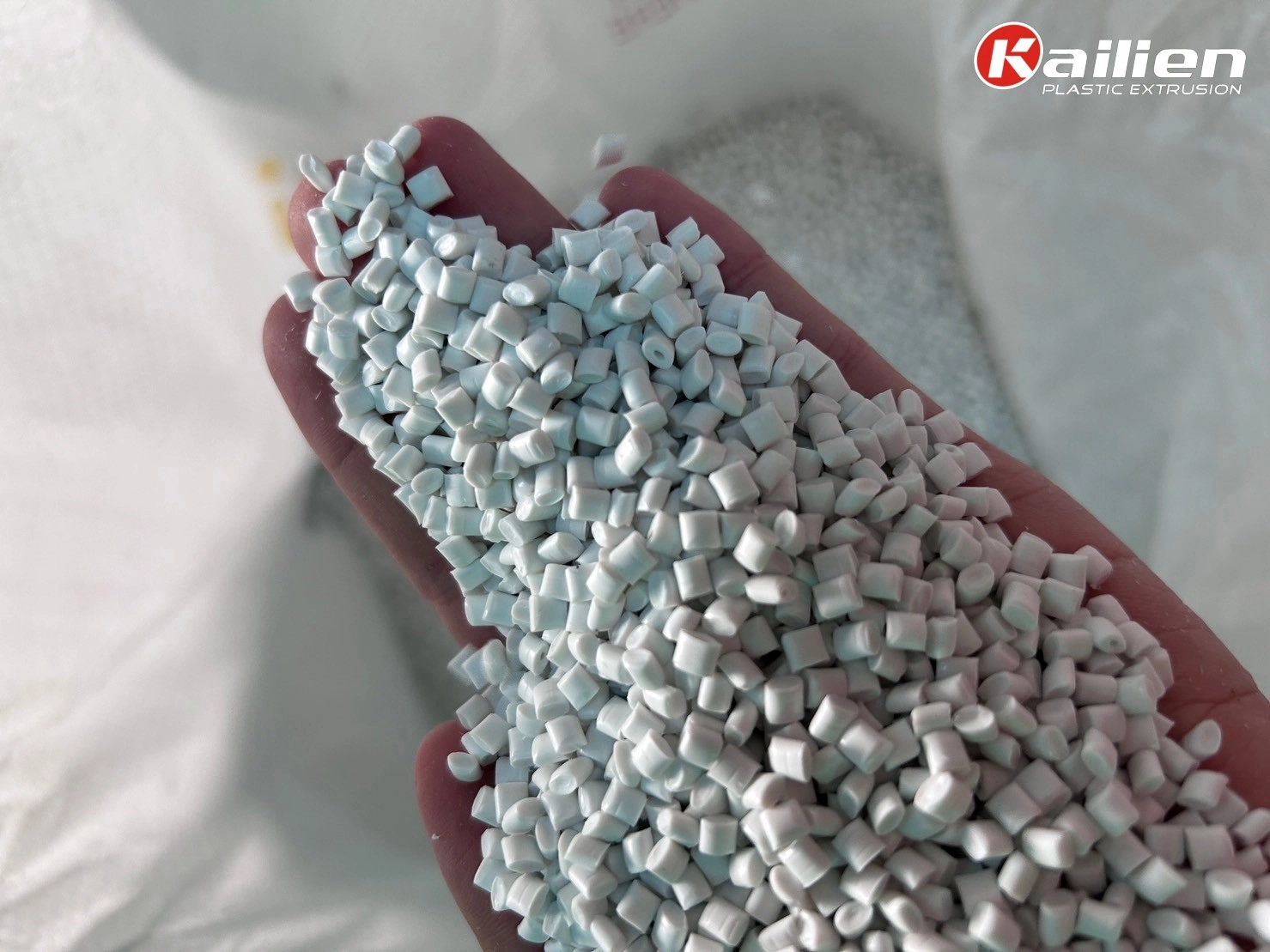

Kailien's hopper-type hard plastic pelletizer is designed specifically to handle the characteristics of engineering plastics, such as PP, PE, and ABS. Its main functions include:

- Waste Processing: Crushing, melting, and re-pelletizing production rejects (e.g., pipes and sheets).

- Quality Assurance: Producing recycled pellets with consistent dimensions and properties for direct use in production

- Energy Efficiency: Simple structure and stable operation make it suitable for in-house recycling.

Cost Advantages of Using Recycling Pelletizers for Factories

Implementing a hopper-type hard plastic pelletizer in a factory offers several cost and efficiency benefits:

- Reducing Raw Material Costs: Recycled plastic pellets can partially replace new materials, reducing dependency on expensive virgin raw materials.

- Lowering Waste Treatment Expenses: Waste no longer needs to be outsourced for processing; it can be recycled internally.

- Enhancing Product Competitiveness: Low-cost, high-quality production increases market competitiveness.

- Long-Term Energy Savings: The machine’s efficient operation reduces energy consumption, further cutting operating costs.

Recycling and reusing engineering plastic waste is not only an effective way to reduce production costs but also an essential pathway to achieving sustainable manufacturing. Kailien’s hopper-type hard plastic pelletizer, through technological innovation and practical applications, helps factories extract new value from production rejects and acts as a critical driver in the circular economy. Choosing such equipment is not just a commitment to the environment but also a responsible choice for the future. We invite more companies to join this green revolution in plastic recycling and move toward a sustainable future together.

Hopper-type hard plastic pelletizer

- Using the SCR system, it can save 25% of electricity, precisely control the temperature deviation within ±1 degree, and save electricity

- Application: PP recycling pellet, PE recycling pellet, ABS recycling pellet

Advantages of Utilizing an Automated Conveying System (Blog)

The Advantages and Application of Twin Screw Pelletizing Extrusion Line (Blog)

If you wish to know more about Recycling Pelletizing Extruder, Contact Kailien's experienced sales team!